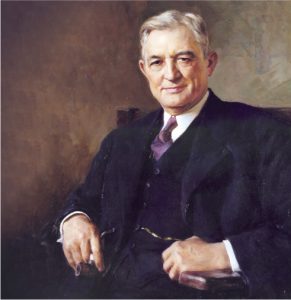

On July 17, 1902, Willis Haviland Carrier designed the first modern air-conditioning system, launching an industry that would fundamentally improve the way we live, work and play.

Biography:

Born November 26, 1876, in Angola, N.Y.

Received engineering degree from Cornell University in 1901

Started working at Buffalo Forge Company in 1901

Designed the world’s first modern air conditioning system in 1902

Developed Rational Psychrometric Formulae in 1911

Founded Carrier Engineering Corporation in 1915

Awarded honorary doctorates from Lehigh University (1935) and Alfred University (1942)

Died October 7, 1950, in New York, N.Y.

Inducted into the National Inventors Hall of Fame in 1985

Named one of TIME magazine’s “100 Most Influential People of the 20th Century” in 1998

A lifetime lesson

Willis Carrier would grow up to solve one of mankind’s most elusive challenges – controlling the indoor environment. As a child, though, he had difficulty grasping the concept of fractions. Realizing his struggles, his mother taught him by cutting whole apples into various-sized fractional pieces. He later said this lesson was the most important one that he ever learned because it taught him the value of intelligent problem-solving.

Willis Carrier: The Inventor of Modern Air Conditioning

Genius can strike anywhere. For Willis Carrier, it was a foggy Pittsburgh train platform in 1902. Carrier stared through the mist and realized that he could dry air by passing it through water to create fog. Doing so would make it possible to manufacture air with specific amounts of moisture in it. Within a year, he completed his invention to control humidity – the fundamental building block for modern air conditioning.

Carrier Enables Industries to Flourish

The “Father of Air Conditioning,” Willis Carrier’s invention gave rise to numerous industries that power our economy today. Manufacturing of everything from baked goods to wartime supplies was made possible by air conditioning. Air conditioning led directly to summer movie blockbusters as people came to cooled theatres to escape the heat. The precise control of temperature and humidity made possible by his invention even enabled shopping malls, transatlantic flight, and the computers and servers that power the Internet.

Bringing Comfort to the World

Willis Carrier recognized early on that climate, comfort and production requirements would determine the value of air conditioning. From the beginning, he began to develop a network of international dealers, distributors and customers. Success with early installations in Europe and Asia were indicators of air conditioning’s universal application across international borders.

Sustaining Carrier’s Vision

Willis Carrier’s legacy lives on today as the company he founded continues to reinvent the industry and shape the world we live in. Carrier leads the industry with energy-efficient products and manufacturing practices. Every day, Carrier brings productivity and comfort to the world through new innovations – all built on energy efficiency and sustainability.

In 1995 was the first time i had to offer a cooling unit for a vehicle for a customer. It was my first cooling unit sale. Looking back it was a miracle that it came to a contract, as I suggested a Thermo King V095 for a 12m 3 vehicle, which is undersized in cooling capacity.

In the 90-s a cold chain (goods requiring cooling transported from the place of production to the place of use) was typically used between a commodity producer and a processor. Goods were loaded on high temperature, and the doors were not opened until the goods arrived to their destination. The summer temperature was also lower than nowadays. Selection guides worked well. The life of transport cooling professionals was easy. No customer complained about a unit with too low capacity.

20 years have passed. The structure of cooled transports changed fundamentally. The most substantial change is, that commodities are transported with trailers, with cooling units that represent the height of cooling technologies. The cooling bodies have ATP certifications (international regulations for the transport on regulated temperature), with homogenous walls of good isolation power.

What is the case with the much smaller vans? For economic reasons the clients wish to transport as much goods as possible, with the least possible isolation material, and lightest cooling units.

Because of the hard competition a cheaper cooling unit can be 800-1000 Euro cheaper. Sellers, who don’t have the client interest as first view can decrease the price of the body building by suggesting a smaller, and this way cheaper, cooling unit.

A good consultant makes a canny decision, wagering the summer high temperature, door opening number, and isolation experiences.

For the best decision both consultant and client have to think of but one viewpoint:

„If the cooling unit is too small, it can’t be made bigger”

We suggest after receiving a quotation ask your consultant if the cooling capacity guarantees the desired temperature even at +40°C ambient heat.

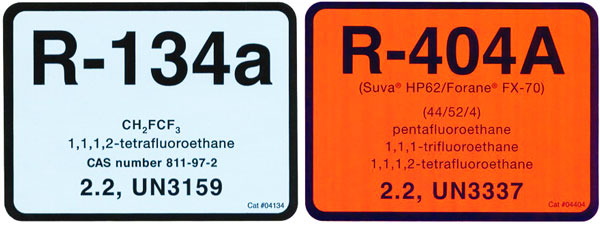

The cooling agent circulating in cooling units can have a direct impact ont he enviroment, if by possible damage, or malfunktion leaks into the air. Some agents contribute to the decay of the ozon layer, others lead to global warming, accelerating the glas house effect.

An indirekt impact is trough the energy consumption of the air condotioning and cooling units, as energy generation leads to CO2 emission, independent if we use the units from elektric networks, or own engines. Carbon.dioxide leads to global warming.

To the understanding of the danger of leaked cooling agents the next illustration can help

GWP= Global Warm Potencional

R404a refrigirating agent GWP=3780

1GWP = 1 Kg CO2

Carbon-dioxide emission of an average car, like a Ford Focus 150g/km

1000 g= 1 Kg CO2

6,7 km x 150 g/km = 1005g so you have to drive 6,7 Km, so your car has an emission of 1 Kg

1kg R 404a = 3780GWP X 6,7km = 25326km

So you would have to drive 25326km to have the same emission as 1 Kg of R404a cooling agent. Usual direkt drive units have 1,5-2 Kg, while trailers units have 7-9 Kg of R404a load on avarage.

This way it is apparent why regular check ups on cooling units are important.

Companies are using high resources to find agents with a global warming factor as low as possible. In January 2017 Carrier Transicold introduced R452a, to replace R404a, that has the same performance parameters, but almost 50% less GWP.

Written by:

Péter Vastag

The two main refrigerants used in transport cooling behave differently with the change of temperature and pressure. This can be presented well with the known example of petrol and diesel engines. While petrol engines have a high torque, diesels work efficiently even at high speed. But these are still engines. Let’s meet the refrigerants!

The R134a refrigerant is used for „normal” cooling, meaning the load compartment does not have to be cooled under 0°C. (This refrigerant is also used in vehicle air conditioners.) If the temperature in the load compartment is lower the pressure of the refrigerant returning to the compressor can sink so low, that the refrigerant cannot function effectively.

If we need a lower temperature – like at the transport of frozen goods- the R404a, or it’s more nature friendly counterpart, the R452a, is the refrigerant we need. This substance has lower pressure needs, so even at lower returning refrigerant pressure the compressor can circulate the refrigerant effectively. The question comes naturally: what happens, when the load compartment temperatures high or the returning refrigerant temperature is low? Can refrigerant pressure get too high? The pressure rises in such cases, but cooling unit producers integrate pressure and flow control valves, that are able to optimize system pressures, even at critical conditions.

The most important factor in transport cooling is efficiency. We can say that you can achieve higher efficiency if you are using the right refrigerant. This also increases the life expectancy of your cooling unit. It is important to note, that the technical details of a unit, the pressure valves, feed valves are set for a given refrigerant. So the changing of the refrigerant to a different type or loading it with a different refrigerant is not suggested, and in most cases not economic. In our engine example this would mean, that you cannot fill the tank of a petrol engine with diesel fuel, because its cheaper.